Introduction

Welcome to the world of custom water cooling! Building a custom loop can be an intimidating but rewarding experience. In this article, I will walk through the basic components needed to build a custom loop, and provide tips on how to maintain it properly.

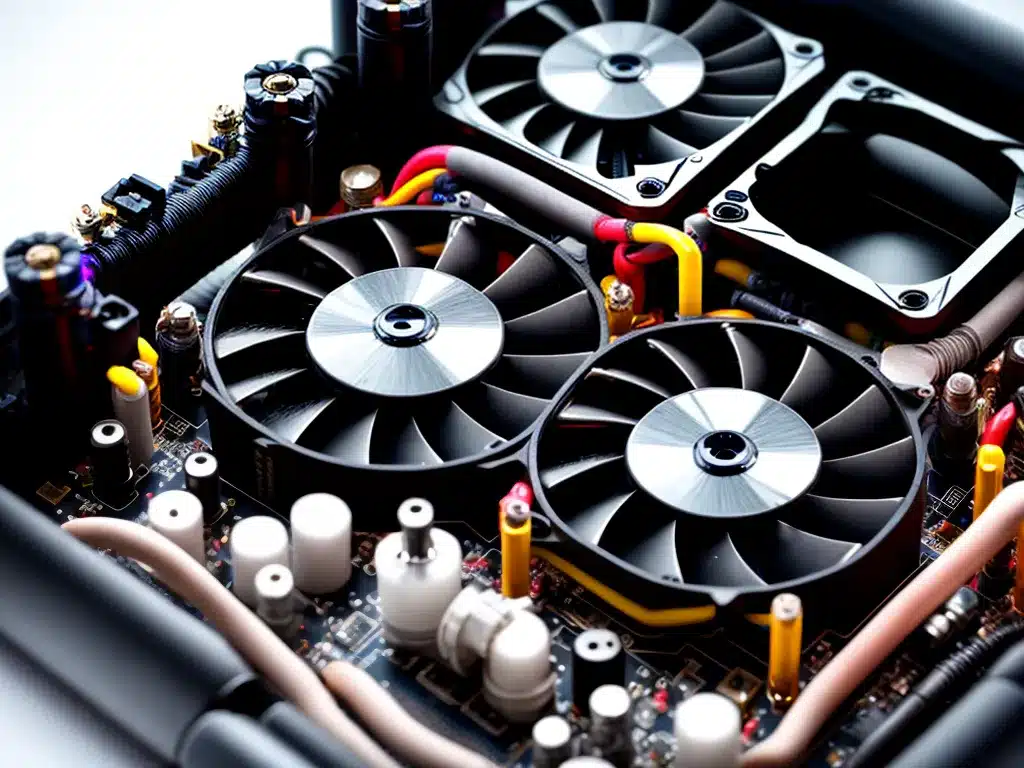

A custom loop consists of many components that work together to provide efficient cooling to your computer’s CPU, GPU, and other components. While complex, a basic understanding of each part will help demystify the process. Proper maintenance is also key to keeping your loop running smoothly for years.

So whether you’re new to water cooling or a seasoned veteran, read on to learn the fundamentals of building and caring for a custom loop. Let’s dive in!

Components

Here are the main components that make up a custom water cooling loop:

Water Blocks

Water blocks are devices that mount directly onto components like the CPU and GPU to absorb heat. They have channels etched into their base to allow water to pass through and make direct contact with the chip surface. More surface area and thinner bases transfer heat better. The material used affects performance too, with copper being the most efficient.

A quality water block tailored for your specific hardware is essential for proper cooling. I always research reviews thoroughly before selecting water blocks to ensure optimal compatibility and cooling capability.

Radiators

Radiators dissipate the heat absorbed by the water blocks into the air. They are made up of tubes and fins which maximize surface area for heat transfer. The larger the radiator, the more heat it can dissipate. Radiator thickness also plays a role, with thicker radiators handling more heat.

Proper radiator size is determined by your loop’s cooling needs. A good rule of thumb is 120mm of radiator per component being cooled, plus an additional 120mm. My loop runs very cool with a thick 360mm radiator for just the CPU.

Pump

The pump circulates fluid through the loop, overcoming resistance from all the components. It needs to be powerful enough to push adequate flow yet quiet enough for silent operation. When selecting a pump, I look at flow rate and noise levels at various speeds.

For most loops, a D5 or DDC pump running at 40-60% power provides sufficient flow with minimal noise. Always buy a name brand pump from a reputable manufacturer for reliability.

Tubing

Tubing carries fluid through the loop, connecting all the components together. The main choices are rigid acrylic or flexible soft tubing. Acrylic provides a clean aesthetic but requires careful measurements, bending, and welding. Soft tubing is easier for beginners to work with due to its flexibility.

For my first loop, I went with soft tubing since it was more forgiving. But I plan to switch to acrylic soon for a sleeker look. Inner diameter should match your fittings for a secure seal.

Fittings

Fittings join tubing segments together and to components, creating a sealed path for the fluid. They come in many styles, but compression fittings are a popular choice. Make sure to get fittings sized appropriately for your tubing’s inner and outer diameter.

I prefer angled adapters for connecting components, as they allow for smoother tubing runs. Rotary fittings are also useful for further adjusting tubing alignment. Using quality fittings ensures leak-free operation.

Coolant

Coolant carries heat through the loop. Plain distilled water works fine, but coolants with anti-corrosive additives are better for preventing buildup and corrosion. Pre-mixed coolants provide the simplest option, though some prefer mixing their own additives.

I’ve had great success using EK CryoFuel premix, which protects my loop for over a year between drains. Make sure to select coolant compatible with your loop materials. Keep an eye on color change, which indicates it’s time for a change.

Reservoir

The reservoir stores extra coolant to offset evaporation over time. It allows easy viewing of the coolant level and provides a convenient fill port. Tube reservoirs mount in many locations, while bay reservoirs install in optical drive bays.

I’m using a cylindrical tube reservoir mounted prominently in my case interior. The level is easy to monitor and refilling is simple. Go with a reliable quality reservoir to prevent any leaks.

Sensors and Controllers

While optional, adding sensors and a controller takes your loop to the next level. Sensors measure coolant temp, flow rate, and other parameters, allowing software control of fans and pump speeds based on actual conditions. This optimizes both cooling and noise.

I’m using an Aqua Computer controller with coolant temp, flow, and pressure sensors. With the software, I created a custom fan curve based on coolant temp for nearly silent operation under light loads. Monitoring flow rate also alerts me to any pump issues.

Maintenance

Properly maintaining a custom loop ensures longevity and peak performance. Here are some tips:

Flush Radiators

Always flush your radiators before installation to remove any debris from manufacturing. I hook up the radiator to my pump and let it run for several hours with hot distilled water, periodically shaking it. Repeat until the rinse water runs clear.

Inspect Fitting O-Rings

Regularly inspect the O-rings inside each fitting and replace if worn. Any deterioration can lead to a leak. I keep spares on hand just in case. Lubricating them during assembly helps seat them properly.

Check Coolant Level

Keep an eye on the coolant level inside your reservoir as it will slowly deplete over time. Top it off with fresh premix as needed to prevent air from entering the loop. A 50% change yearly is ideal for long-term operation.

Monitor Temperatures

Use software like HWiNFO to track component temps. If you notice a steady rise over time it could indicate buildup inside your blocks. Time to flush out and clean the loop. My temps have remained consistent for over two years.

Dust Radiators

Use compressed air to regularly blast dust out of your radiators to maintain optimal airflow. Any buildup on the fins will reduce cooling capacity. I like to take my radiators outside a few times a year for a thorough cleaning.

Conclusion

Building a custom water cooling loop requires careful selection of quality components and ongoing maintenance to keep it running flawlessly. Following the tips outlined in this guide will help you achieve an efficient, reliable system. Don’t be intimidated by the process—take it slow and you’ll have an awesome setup in no time. Let me know if you have any other water cooling questions!