The Importance of Sustainable Supply Chains

In today’s increasingly competitive and environmentally conscious business landscape, sustainability has emerged as a critical priority for enterprises across industries. Sustainable supply chain management (SSCM) has become a strategic imperative, as organizations strive to minimize their environmental impact, optimize resource utilization, and enhance long-term competitiveness.

The rise of sustainable supply chains is driven by a convergence of factors – stricter environmental regulations, growing consumer demand for eco-friendly products, and the need to future-proof operations against disruptions. Enterprises that embrace sustainable supply chain strategies and practices can not only reduce their carbon footprint but also unlock significant business benefits, such as improved efficiency, cost savings, and enhanced brand reputation.

At the heart of SSCM lies the concept of the circular economy – a regenerative approach that aims to keep materials and resources in use for as long as possible, extracting maximum value and then recovering and regenerating products and materials at the end of their service life. By adopting circular economy principles, organizations can transform their linear supply chains into closed-loop, sustainable systems that minimize waste and foster long-term resilience.

Sustainable Supply Chain Strategies

Sustainable supply chain strategy is a holistic, organization-wide approach that aligns a company’s business objectives with sustainability goals. This strategic framework encompasses various elements, including:

1. Sustainable Sourcing: Identifying and selecting suppliers that adhere to environmental, social, and governance (ESG) standards, prioritizing renewable, recyclable, and ethically-sourced materials.

2. Sustainable Production: Implementing eco-friendly manufacturing processes, leveraging renewable energy, and minimizing waste and emissions throughout the production cycle.

3. Sustainable Packaging: Designing packaging solutions that are recyclable, biodegradable, or reusable, reducing the environmental impact of product distribution.

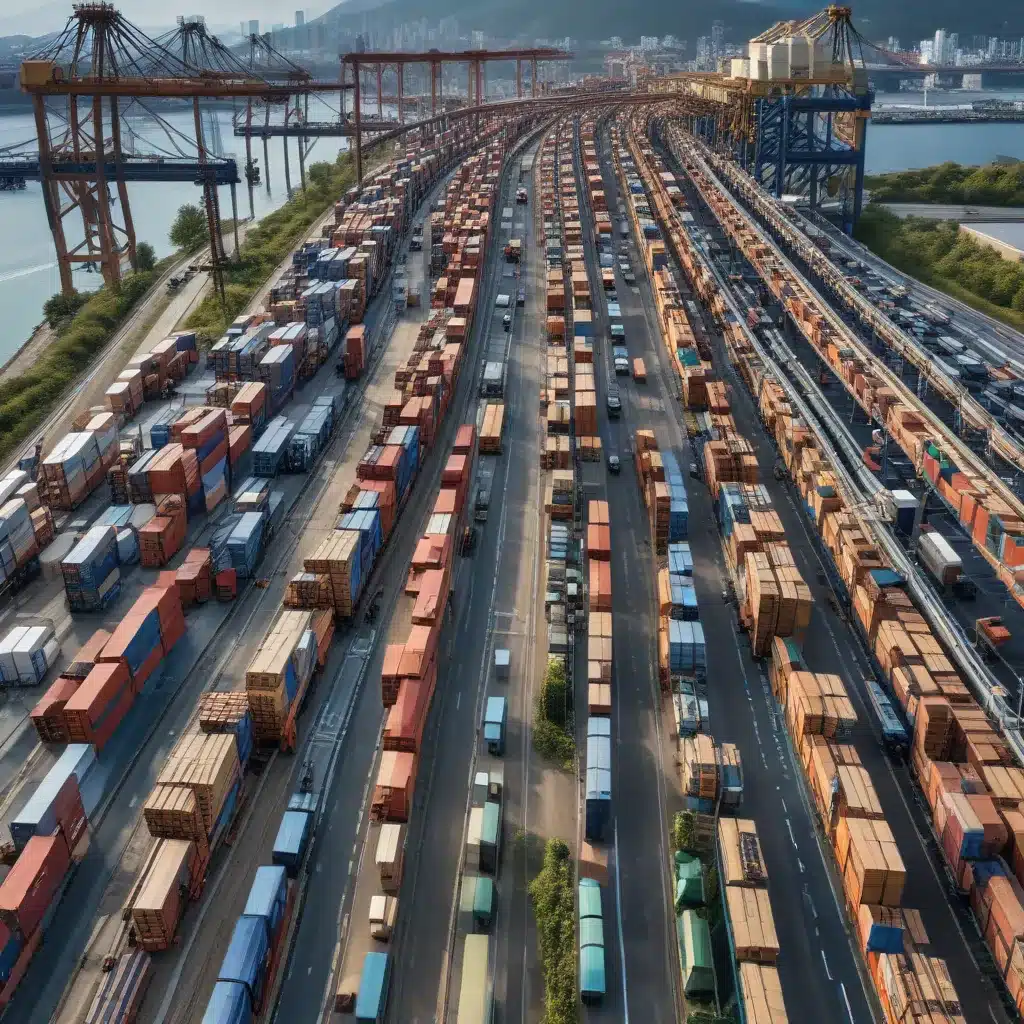

4. Sustainable Logistics: Optimizing transportation routes, utilizing alternative fuel vehicles, and maximizing load efficiency to reduce greenhouse gas emissions and fuel consumption.

5. End-of-Life Management: Incorporating product take-back programs, remanufacturing, and recycling initiatives to extend the useful life of materials and minimize landfill waste.

By aligning these strategic elements, organizations can create a comprehensive, sustainable supply chain that delivers long-term value for the business, the environment, and society.

The Role of Industry 4.0 in Sustainable Supply Chains

The emergence of Industry 4.0 technologies has significantly transformed the landscape of supply chain management, enabling new opportunities for sustainable practices. Industry 4.0 refers to the integration of advanced digital technologies, such as the Internet of Things (IoT), big data analytics, artificial intelligence (AI), and automation, into manufacturing and supply chain processes.

These transformative technologies have the potential to enhance the sustainability of supply chains in several ways:

-

Visibility and Traceability: IoT sensors and connected devices can provide real-time visibility into supply chain operations, allowing for better tracking of resource consumption, emissions, and waste generation.

-

Predictive Maintenance: AI-powered predictive analytics can identify potential equipment failures and enable proactive maintenance, reducing energy use and extending the lifespan of assets.

-

Intelligent Routing and Optimization: Advanced analytics and automation can optimize transportation routes, improve load planning, and reduce fuel consumption and emissions.

-

Circular Economy Integration: Digital technologies can facilitate the reuse, remanufacturing, and recycling of materials, enabling the transition to a more circular supply chain model.

-

Collaborative Platforms: Cloud-based supply chain management platforms can foster greater transparency and collaboration among supply chain partners, facilitating the implementation of sustainable practices.

By seamlessly integrating Industry 4.0 capabilities into their supply chain strategies, organizations can enhance sustainability, improve operational efficiency, and gain a competitive edge in the market.

Sustainable Supply Chain Practices

Alongside the strategic framework, sustainable supply chain practices are the operational manifestations of an organization’s commitment to sustainability. These practices span various aspects of the supply chain, including:

-

Sustainable Sourcing: Conducting supplier audits, implementing supplier codes of conduct, and collaborating with partners to ensure compliance with environmental and social standards.

-

Green Procurement: Prioritizing the procurement of eco-friendly, energy-efficient, and recycled materials and products.

-

Lean and Agile Operations: Adopting lean manufacturing principles, such as waste reduction and just-in-time production, to optimize resource utilization.

-

Closed-Loop Logistics: Implementing reverse logistics, product take-back programs, and remanufacturing initiatives to extend the life cycle of products and materials.

-

Sustainable Packaging: Designing and using packaging solutions that are biodegradable, recyclable, or reusable, minimizing waste and environmental impact.

-

Renewable Energy Integration: Incorporating renewable energy sources, such as solar, wind, or geothermal, into manufacturing and distribution operations.

-

Stakeholder Engagement: Collaborating with customers, suppliers, and local communities to align sustainability goals and foster a culture of environmental stewardship.

By consistently implementing these sustainable supply chain practices, organizations can drive tangible improvements in their environmental, social, and economic performance, ultimately enhancing their competitive advantage in the marketplace.

The Benefits of Sustainable Supply Chains

Embracing sustainable supply chain strategies and practices can unlock a wide range of benefits for organizations, including:

-

Cost Savings: Reduced energy consumption, waste management, and efficient resource utilization can lead to significant cost savings throughout the supply chain.

-

Improved Efficiency: Sustainable practices, such as lean manufacturing and predictive maintenance, can enhance operational efficiency and productivity.

-

Enhanced Brand Reputation: Demonstrating a commitment to sustainability can improve brand perception, customer loyalty, and stakeholder trust.

-

Regulatory Compliance: Aligning with evolving environmental regulations and industry standards can help organizations avoid penalties and maintain legal and social license to operate.

-

Increased Resilience: Sustainable supply chains are better equipped to withstand disruptions, such as resource scarcity, supply chain shocks, and climate-related events.

-

Talent Attraction and Retention: Sustainability-focused organizations can attract and retain top talent who seek to work for environmentally and socially responsible companies.

-

Competitive Advantage: Successful implementation of sustainable supply chain strategies can differentiate an organization from its competitors and drive long-term market success.

By strategically aligning sustainability across their supply chain operations, organizations can create a positive impact on the environment, society, and their own business performance, ultimately enhancing their competitiveness and long-term viability.

Overcoming Sustainability Challenges

Despite the clear benefits of sustainable supply chains, organizations may face various challenges in implementing and maintaining sustainable practices. Some of the key obstacles include:

-

Organizational Inertia: Resistance to change, lack of executive buy-in, and organizational silos can hinder the adoption of sustainable supply chain initiatives.

-

Supplier Engagement: Aligning suppliers with sustainability goals and ensuring compliance across multi-tier supply chains can be complex and resource-intensive.

-

Technology Integration: Integrating advanced digital technologies, such as IoT and AI, into existing supply chain infrastructure can require significant investment and technical expertise.

-

Data Availability and Quality: Lack of reliable, real-time data on sustainability metrics can make it difficult to measure and track the impact of sustainable practices.

-

Financial Constraints: The upfront costs associated with sustainable investments, such as renewable energy or closed-loop systems, can be a barrier for some organizations.

-

Regulatory Uncertainty: Evolving environmental regulations and policies can create challenges for organizations in maintaining compliance and adapting their supply chain strategies.

To overcome these challenges, organizations must adopt a holistic, collaborative approach that involves:

- Securing top-down commitment and leadership support for sustainability initiatives

- Fostering a culture of sustainability throughout the organization

- Engaging suppliers and partners to align on sustainability goals

- Leveraging Industry 4.0 technologies to enhance visibility, traceability, and data-driven decision-making

- Exploring innovative financing models, such as green bonds or sustainability-linked loans, to fund sustainable investments

- Staying agile and adaptable to navigate changing regulatory landscapes

By proactively addressing these challenges, organizations can successfully implement and sustain their sustainable supply chain strategies, positioning themselves for long-term success in the increasingly competitive and environmentally conscious business environment.

Conclusion

In the modern era, sustainable supply chain management has emerged as a critical strategic imperative for organizations across industries. By aligning their business objectives with sustainability goals, enterprises can not only reduce their environmental impact but also unlock a wide range of business benefits, including cost savings, improved efficiency, enhanced brand reputation, and increased resilience.

The integration of Industry 4.0 technologies, such as the Internet of Things, big data analytics, and artificial intelligence, has further transformed the landscape of sustainable supply chains, enabling new opportunities for visibility, optimization, and circular economy integration.

To effectively implement sustainable supply chain strategies and practices, organizations must overcome various challenges, ranging from organizational inertia to financial constraints. By adopting a holistic, collaborative approach and leveraging the power of digital technologies, enterprises can navigate these obstacles and position themselves for long-term success in the increasingly competitive and environmentally conscious business landscape.

As the global emphasis on sustainability continues to grow, organizations that embrace sustainable supply chain management will not only contribute to environmental and social welfare but also gain a significant competitive edge in the market. By aligning their supply chain strategies and practices with the principles of sustainability, enterprises can create a positive impact on the planet, their stakeholders, and their own long-term viability.