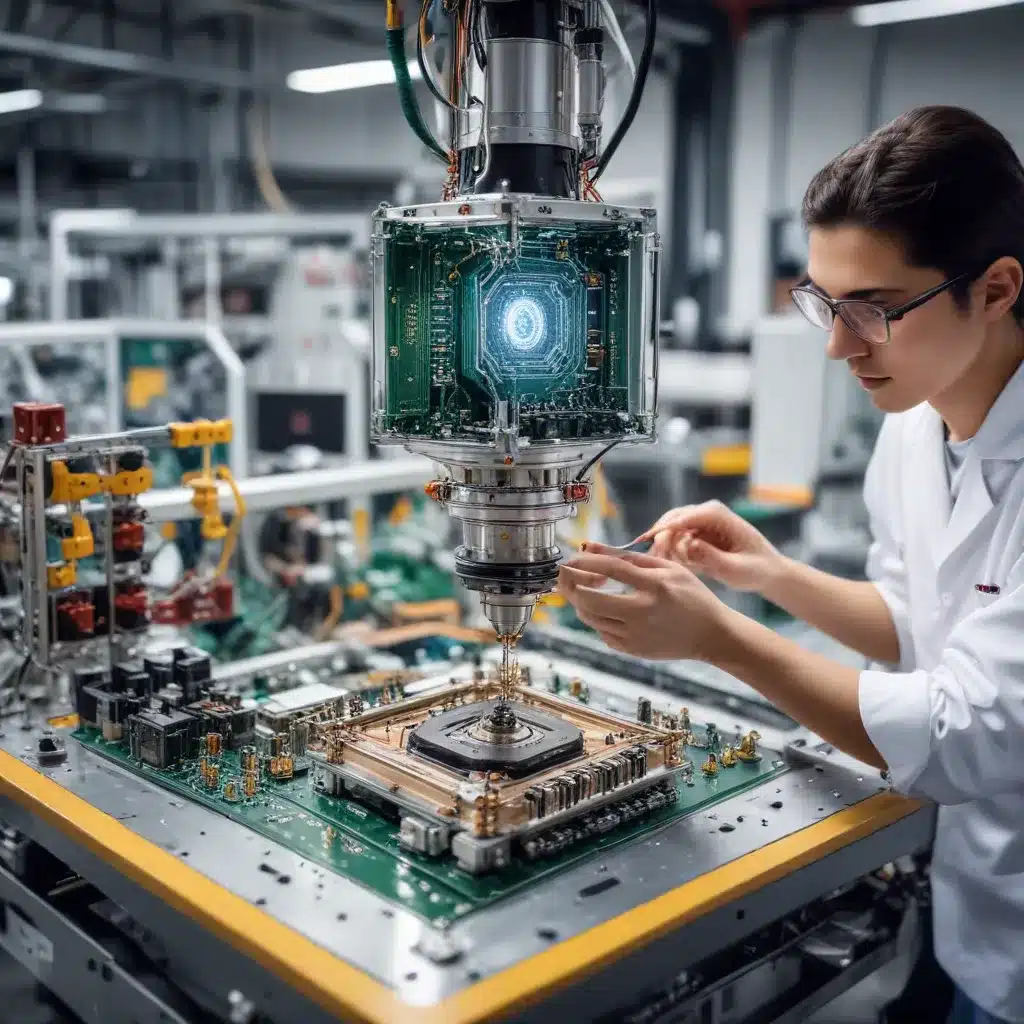

The Quantum Computing Revolution: Unlocking New Possibilities for Precision Manufacturing

In the rapidly evolving landscape of quantum computing, a select group of pioneering companies are making remarkable strides, pushing the boundaries of what was once thought impossible. Among these trailblazers is Google, whose Quantum AI division has been at the forefront of harnessing the power of quantum technology to revolutionize various industries, including the realm of precision manufacturing.

Quantum Supremacy and Beyond: Google’s Quantum Computing Milestones

Google’s journey in quantum computing has been marked by several groundbreaking achievements. In October 2019, the company made headlines with its announcement of achieving “quantum supremacy” – a milestone where a quantum computer performed a calculation that would be practically impossible for a classical computer to complete in a reasonable timeframe.

This landmark accomplishment was the result of the tireless efforts of the Google Quantum AI team, led by Engineering Director Hartmut Neven. The team’s relentless pursuit of innovation has continued to yield impressive advancements, including the development of cutting-edge quantum hardware and software solutions tailored for practical applications.

Quantum-Enhanced Quality Control: Reducing Errors and Optimizing Processes

One of the areas where Google’s quantum computing prowess shines is in the realm of quality control and process optimization for precision manufacturing. By leveraging the unique properties of quantum mechanics, the company has been able to develop innovative techniques that can significantly enhance the efficiency and reliability of manufacturing processes.

Quantum Error Reduction

A key challenge in manufacturing is the mitigation of errors and defects in the production pipeline. Quantum computing offers a unique solution to this problem. Through the strategic use of quantum algorithms and error correction techniques, Google’s Quantum AI team has demonstrated the ability to reduce quantum computing errors by a substantial margin.

This achievement was highlighted in a recent blog post authored by the company’s CEO, who detailed the team’s success in increasing the number of qubits, transitioning to a logical qubit approach, and enhancing overall system performance. By addressing these critical factors, Google has made significant strides in creating more robust and reliable quantum computing systems that can be applied to precision manufacturing tasks.

Quantum-Enhanced Process Optimization

In addition to error reduction, Google’s quantum computing prowess has also enabled advancements in process optimization. Quantum algorithms, such as the Quantum Approximate Optimization Algorithm (QAOA) and the Variational Quantum Eigensolver (VQE), have demonstrated the ability to solve complex optimization problems more efficiently than classical algorithms.

These quantum-enhanced optimization techniques can be applied to various manufacturing processes, from supply chain logistics and resource allocation to product design and quality control. By leveraging the unique properties of quantum computing, manufacturers can explore a wider range of solutions, identify optimal configurations, and make data-driven decisions that lead to increased efficiency, reduced waste, and improved product quality.

Quantum Sensing for Enhanced Metrology and Inspection

Alongside its advancements in quantum-enhanced quality control, Google’s Quantum AI division has also made significant strides in the realm of quantum sensing. Quantum sensors, which harness the principles of quantum mechanics, have the potential to revolutionize metrology and inspection processes in precision manufacturing.

Quantum Magnetometers for Defect Detection

One notable example is the development of quantum magnetometers, which can detect even the most minute magnetic field variations. These sensors can be deployed in manufacturing environments to identify defects, material flaws, and other anomalies that may be invisible to traditional inspection methods.

By leveraging the sensitivity of quantum magnetometers, manufacturers can implement more thorough and accurate quality control measures, ensuring that products meet the highest standards of precision and reliability.

Quantum Gravimeters for Structural Integrity Monitoring

Another area of quantum sensing innovation is the use of quantum gravimeters, which can measure gravitational fields with unprecedented accuracy. These sensors can be employed to monitor the structural integrity of manufacturing facilities, detecting even the slightest changes in the gravitational field that may indicate potential issues or deformations.

This capability is particularly valuable in industries where the structural stability of production environments is critical, such as in the aerospace, automotive, and heavy machinery sectors. By utilizing quantum gravimeters, manufacturers can proactively identify and address any structural concerns, preventing costly downtime and ensuring the safety of their operations.

Integrating Quantum Computing into the Manufacturing Ecosystem

As Google’s Quantum AI division continues to push the boundaries of quantum computing, the company is also actively working on seamlessly integrating these technologies into the broader manufacturing ecosystem. This integration is crucial for enabling the widespread adoption and practical application of quantum-enhanced quality control and process optimization.

Collaboration and Knowledge Sharing

To facilitate this integration, Google has fostered strong partnerships with leading manufacturing organizations, research institutions, and industry experts. By engaging in collaborative efforts, the company is able to gather valuable insights, identify specific pain points, and tailor its quantum computing solutions to meet the unique needs of the manufacturing sector.

Through knowledge-sharing initiatives, workshops, and joint research projects, Google is helping to bridge the gap between the cutting-edge world of quantum computing and the practical realities of modern manufacturing. This collaboration ensures that the benefits of quantum technology are not limited to the lab but can be translated into tangible improvements in production efficiency, product quality, and overall competitiveness.

Quantum Computing as a Service (QCaaS)

Another key strategy employed by Google is the provision of Quantum Computing as a Service (QCaaS). By offering access to its quantum computing resources and expertise through cloud-based platforms, the company is making these transformative technologies more accessible to manufacturers of all sizes.

This QCaaS model allows manufacturers to leverage the power of quantum computing without the need for significant upfront investments in hardware and infrastructure. Instead, they can seamlessly integrate quantum-enhanced capabilities into their existing workflows, enabling them to reap the benefits of improved quality control, process optimization, and enhanced metrology without the burden of managing the underlying quantum technology.

The Future of Quantum-Enhanced Manufacturing: Embracing the Quantum Advantage

As the integration of quantum computing and precision manufacturing continues to evolve, the potential for groundbreaking advancements is immense. Google’s Quantum AI division has demonstrated the ability to push the boundaries of what is possible, and the company’s unwavering commitment to innovation is poised to transform the manufacturing landscape.

Achieving Quantum Advantage

The ultimate goal for Google, and the broader quantum computing community, is to reach the coveted state of “quantum advantage” – a point where quantum computers can outperform classical computers on specific tasks. This milestone would unlock a new era of computational power, enabling manufacturers to tackle challenges that were previously considered intractable.

By leveraging quantum-enhanced quality control, process optimization, and metrology, manufacturers can expect to see significant improvements in productivity, efficiency, and product quality. These advancements could lead to cost savings, reduced waste, and increased competitiveness in the global marketplace.

Toward a Quantum-Powered Future

As the quantum revolution continues to unfold, it is clear that the integration of these transformative technologies with precision manufacturing will be a driving force in the years to come. Google’s Quantum AI division is leading the charge, demonstrating the immense potential of quantum computing to revolutionize the way we approach manufacturing challenges.

By embracing the power of quantum sensing, error reduction, and process optimization, manufacturers can unlock new levels of precision, efficiency, and innovation. As the technology continues to mature and become more accessible, the future of quantum-enhanced manufacturing promises to be one of unprecedented advancements, ushering in a new era of productivity, quality, and competitiveness.