The Rise of Quantum Sensing in Industry 4.0

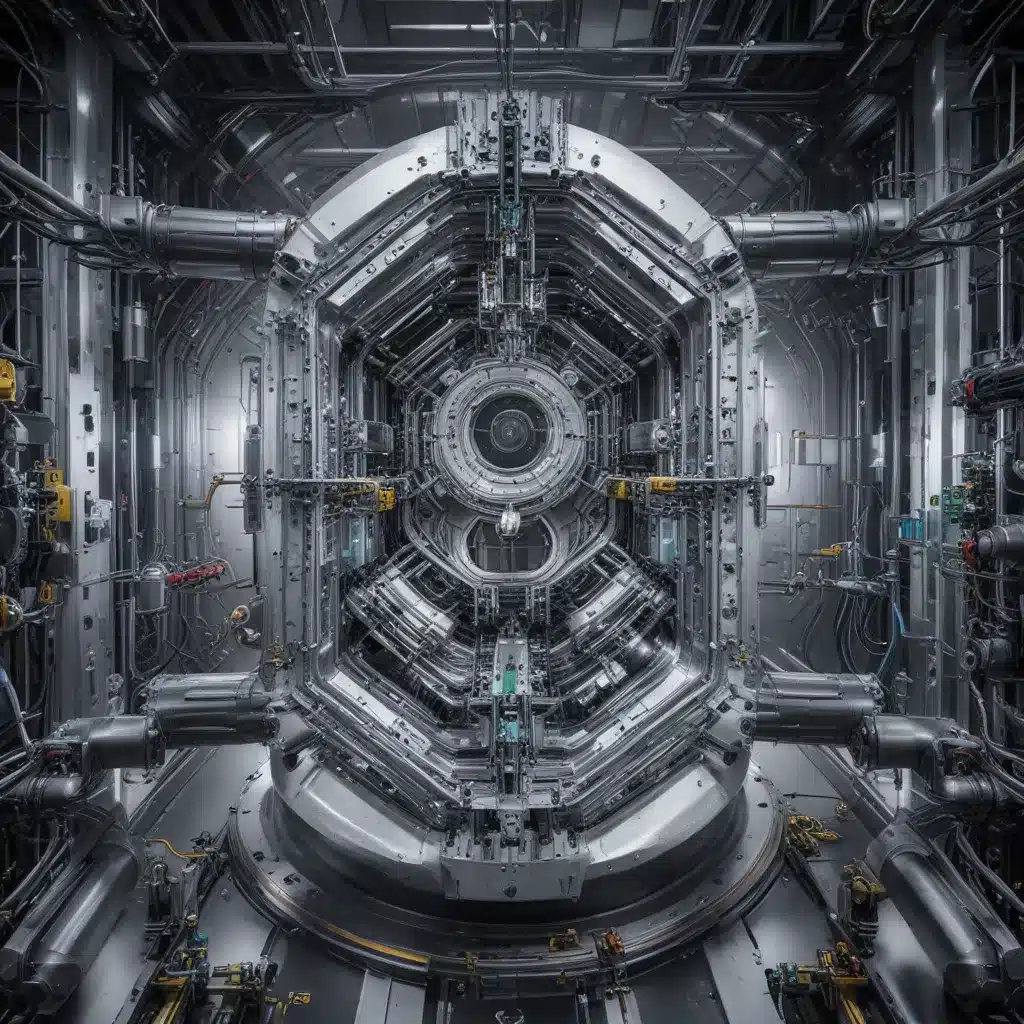

The fusion of quantum computing and artificial intelligence (AI) is ushering in a transformative era for Industry 4.0, offering unprecedented capabilities and challenges. At the forefront of this revolution is the integration of quantum sensing, a technology that harnesses the principles of quantum mechanics to enable highly precise measurements and monitoring of industrial processes.

One of the pioneering organizations at the intersection of quantum sensing and Industry 4.0 is Google. Through its Quantum Artificial Intelligence Lab, the tech giant has been spearheading innovative research and development in this domain, showcasing the potential of quantum-enhanced industrial process monitoring.

Google’s Quantum Sensing Advancements

Google’s quantum sensing initiatives are rooted in the company’s broader strategy to leverage quantum technologies for practical applications. The Quantum Artificial Intelligence Lab, a collaborative effort involving Google, NASA, and the Universities Space Research Association, has been at the forefront of these endeavors.

Quantum Supremacy Milestone

In 2019, the Quantum Artificial Intelligence Lab made headlines when it announced the achievement of quantum supremacy. By demonstrating the superiority of a quantum computer in performing a specific task compared to the world’s most powerful classical supercomputers, Google’s researchers highlighted the transformative potential of quantum computing.

This milestone was a crucial stepping stone in the company’s pursuit of quantum-enhanced industrial applications, as it validated the capabilities of quantum hardware and paved the way for further advancements.

Quantum Sensing for Process Monitoring

Building on its quantum supremacy achievement, Google has been focusing on the integration of quantum sensing into industrial processes. The company’s quantum sensing research aims to address the critical need for precise, real-time monitoring and control of manufacturing operations, a key requirement for Industry 4.0.

One of the primary areas of focus for Google’s quantum sensing initiatives is the development of quantum-enhanced sensors for process monitoring. These sensors leverage the unique properties of quantum systems, such as entanglement and superposition, to achieve unprecedented levels of sensitivity and accuracy.

Quantum Magnetometers for Precision Measurement

A prime example of Google’s quantum sensing innovations is the development of quantum magnetometers. These devices utilize the quantum properties of atomic spins to measure magnetic fields with extraordinary precision, enabling the monitoring of subtle changes in the manufacturing environment.

By deploying these quantum magnetometers in industrial settings, Google aims to provide manufacturers with a powerful tool for real-time process optimization and quality control. The enhanced sensitivity of these sensors allows for the detection of even the slightest deviations in critical parameters, empowering manufacturers to make informed decisions and maintain tight control over their production processes.

Quantum Gyroscopes for Improved Motion Sensing

Another area of focus for Google’s quantum sensing research is the development of quantum gyroscopes. These devices harness the quantum properties of light to measure rotational motion with unparalleled accuracy, a crucial capability for monitoring the precise movements of industrial machinery and equipment.

The integration of quantum gyroscopes into manufacturing environments can provide manufacturers with valuable insights into the performance and efficiency of their production lines. By detecting minute changes in the orientation and movement of components, these sensors can help identify potential issues, optimize maintenance schedules, and enhance overall process reliability.

Quantum Clocks for Synchronization and Time-Keeping

Precise timekeeping is essential in many industrial processes, from coordinating logistics to ensuring the synchronization of various systems. Google’s quantum sensing research has also focused on the development of quantum clocks, which leverage the inherent stability of atomic transitions to provide highly accurate time-keeping capabilities.

By incorporating quantum clocks into their manufacturing operations, companies can benefit from improved process synchronization, enhanced data analysis, and better decision-making based on real-time, high-precision time-stamps.

Challenges and Considerations for Quantum Sensing Adoption

While the potential of quantum sensing in Industry 4.0 is immense, there are several challenges and considerations that need to be addressed for widespread adoption.

Scalability and Cost Efficiency

One of the primary hurdles is the scalability and cost-effectiveness of quantum sensing technologies. Current quantum devices often require complex and expensive infrastructure, such as cryogenic cooling systems, which can limit their accessibility and integration into industrial settings.

Google and other industry leaders are actively working to address these challenges, exploring ways to miniaturize quantum sensors and develop more cost-effective manufacturing processes. As these advancements continue, the adoption of quantum sensing in Industry 4.0 is expected to become more feasible.

Integration with Existing Systems

Another key consideration is the seamless integration of quantum sensing technologies with the existing industrial control and monitoring systems. Manufacturers will need to ensure that these new quantum-enhanced capabilities can be seamlessly integrated into their existing infrastructure, without disrupting ongoing operations or requiring extensive reconfiguration.

Google’s approach to this challenge involves the development of user-friendly software and hardware interfaces, enabling a smooth transition for manufacturers looking to incorporate quantum sensing into their production processes.

Data Processing and Analytics

The vast amounts of data generated by quantum sensors will also require advanced data processing and analytics capabilities. Manufacturers will need to invest in robust data management systems and AI-powered analytical tools to extract meaningful insights from the high-precision sensor data.

Google’s expertise in machine learning and AI is expected to play a crucial role in addressing this challenge, as the company leverages its computational capabilities to develop tailored analytics solutions for quantum sensor data.

The Path Forward: Quantum Sensing and Industry 4.0

As Google and other industry leaders continue to push the boundaries of quantum sensing, the integration of these technologies into Industry 4.0 is poised to transform the manufacturing landscape. By providing unprecedented levels of precision, real-time monitoring, and process optimization, quantum sensing will empower manufacturers to enhance efficiency, improve quality, and reduce waste – ultimately driving the next wave of industrial innovation.

The IT Fix blog will continue to monitor the advancements in quantum sensing and its applications in the industrial sector. Stay tuned for more in-depth insights and practical tips on leveraging these cutting-edge technologies to revolutionize your manufacturing operations.