Electronics Repair

Liquid Damage Assessment

When it comes to electronics, water and other liquids can be the bane of our existence. Whether it’s a spilled drink, a rainy day, or an accidental submersion, liquid damage can wreak havoc on our beloved gadgets. As an experienced IT technician, I’ve seen my fair share of liquid-damaged devices, and I’m here to share my knowledge on how to diagnose and repair them.

Identifying Liquid Damage

The first step in addressing liquid damage is to identify the extent of the issue. Look for visible signs of moisture, such as water droplets, condensation, or discoloration on the device’s exterior. If the device has been submerged, there may be water trapped inside the casing or seeping into the internal components.

Classifying Liquid Damage Types

Not all liquid damage is created equal. The severity of the damage can vary depending on the type of liquid, the duration of exposure, and the specific components affected. Generally, we can classify liquid damage into three categories:

-

Minor Splash or Spill: This type of damage occurs when a small amount of liquid comes into contact with the device, such as a few drops of water or a small spill. The impact is usually minimal, and the device may continue to function with proper cleaning and drying.

-

Partial Submersion: When a device is partially submerged in a liquid, the damage can be more extensive. The liquid may penetrate into the device’s openings, such as ports, buttons, or vents, causing corrosion and short-circuiting.

-

Full Submersion: The most severe form of liquid damage occurs when a device is completely submerged in a liquid. In this case, the liquid can infiltrate every nook and cranny, leading to widespread damage to the internal components and potentially rendering the device unusable.

Safety Considerations

When dealing with liquid-damaged electronics, it’s crucial to prioritize safety. Always unplug the device from any power source and remove the battery, if possible, to prevent electrical shocks or further damage. Avoid touching any exposed metal parts, and work in a well-ventilated area to minimize the risk of inhaling any fumes or vapors.

Disassembly and Inspection

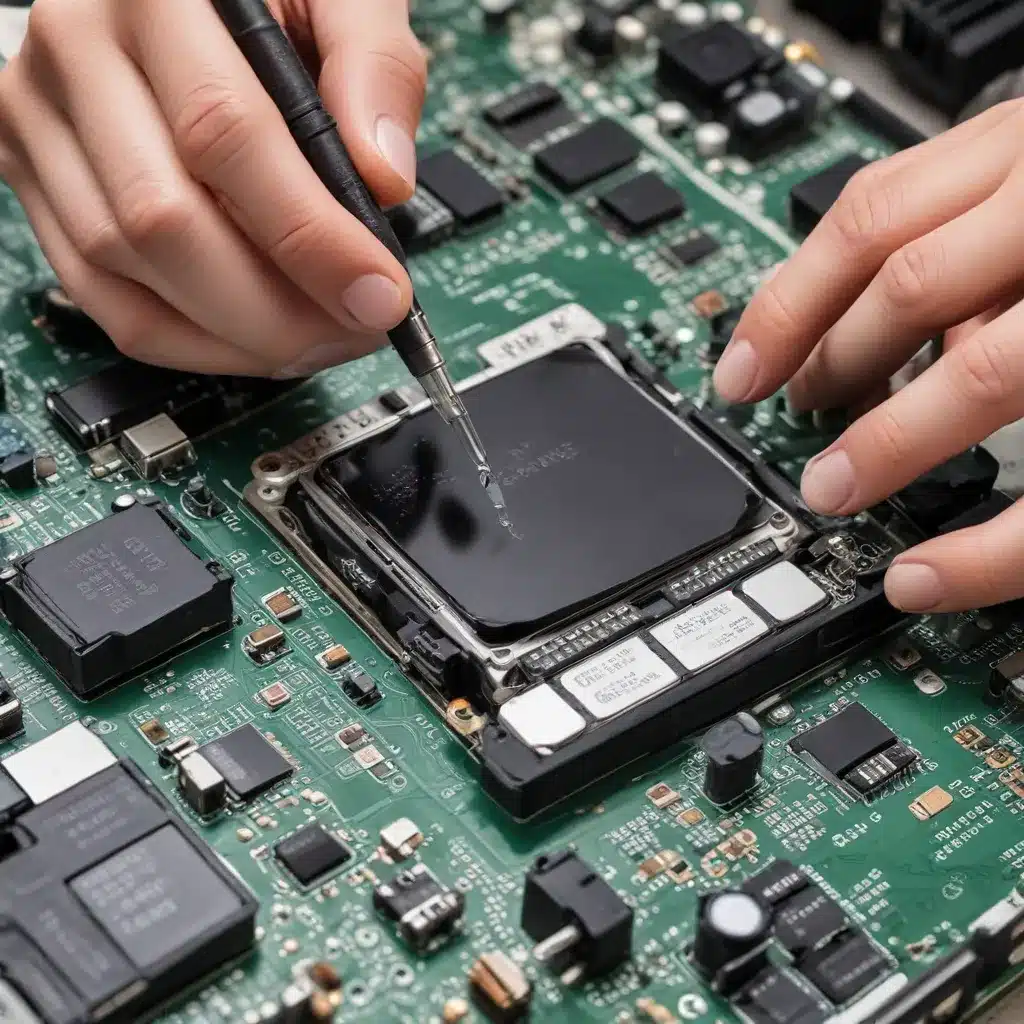

Safely Opening Electronic Devices

Once you’ve assessed the liquid damage, the next step is to carefully disassemble the device. This process requires patience and attention to detail to avoid causing additional harm. Use the appropriate tools, such as precision screwdrivers and tweezers, to gently remove the device’s casing and internal components.

Identifying Affected Components

Examine the internal components of the device, looking for any signs of corrosion, rust, or water damage. Pay close attention to the circuit board, connectors, and any other sensitive electronic parts that may have been exposed to the liquid.

Damage Extent Evaluation

Assess the extent of the damage by inspecting each component. Look for discoloration, oxidation, or physical deformation, which can indicate the severity of the liquid exposure. This information will help you determine the best course of action for the repair process.

Cleaning and Drying Procedures

Cleaning Techniques for Electronics

Once you’ve identified the affected components, it’s time to start the cleaning process. Use a soft, lint-free cloth and isopropyl alcohol (rubbing alcohol) to gently wipe away any visible dirt, debris, or corrosion. Avoid using water or any other liquid, as this can further damage the device.

Proper Drying Methods

After cleaning, the device must be thoroughly dried to prevent further corrosion or short-circuiting. Place the device in a well-ventilated, dry area and allow it to air-dry for at least 24-48 hours. You can also use a dehumidifier or silica gel packets to help absorb any remaining moisture.

Preventing Further Corrosion

To prevent further corrosion, consider applying a thin layer of contact cleaner or electrical component protector to the affected areas once the device is fully dried. This can help create a barrier against future liquid exposure and minimize the risk of future damage.

Component Replacement and Repair

Sourcing Replacement Parts

If the liquid damage has caused irreparable harm to certain components, you’ll need to source replacement parts. This may involve searching online for compatible components or contacting the device manufacturer for specific replacement options.

Soldering and Desoldering Techniques

Replacing damaged components often requires soldering and desoldering skills. Use a high-quality soldering iron and a desoldering pump or wick to carefully remove and replace the affected parts. This process requires a steady hand and attention to detail to avoid further damage.

Functionality Testing

After completing the repair, it’s essential to thoroughly test the device’s functionality. Power on the device and check for proper operation of all its features, including the display, ports, and any other critical components.

Diagnostics and Troubleshooting

Electrical Testing of Components

If the device still isn’t functioning correctly after the repair, you may need to perform more in-depth diagnostics. Use a multimeter to test the electrical continuity and voltage of the affected components, looking for any short circuits or malfunctions.

Identifying Short Circuits and Malfunctions

Liquid damage can sometimes cause short circuits or other electrical issues that are not immediately apparent. Carefully inspect the circuit board and use diagnostic tools to isolate and identify any underlying problems that may be preventing the device from working properly.

Isolating and Resolving Issues

Once you’ve identified the root cause of the issue, you can take the necessary steps to resolve it. This may involve further cleaning, component replacement, or even more extensive repairs, depending on the severity of the damage.

Best Practices and Preventive Measures

Liquid Damage Mitigation Strategies

To minimize the risk of liquid damage to your electronics, consider implementing the following strategies:

- Use waterproof or water-resistant cases or covers for your devices.

- Avoid using your devices in or near areas with high moisture or water exposure.

- Immediately power off and unplug your device if it comes into contact with liquid.

- Seek professional help if you’re unsure about the extent of the damage or the repair process.

Protective Equipment and Precautions

When working on liquid-damaged electronics, always wear appropriate personal protective equipment (PPE), such as nitrile gloves and safety goggles. This will help safeguard you from any potential hazards, such as electrical shocks or chemical exposure.

Maintenance and Storage Recommendations

Proper maintenance and storage can also help prevent liquid damage in the first place. Keep your devices clean and dry, and store them in a cool, dry place when not in use. Regular backups of your important data can also help mitigate the impact of any potential liquid damage.

Liquid damage can be a frustrating and potentially costly issue, but with the right knowledge and approach, it’s often possible to restore your beloved electronics to their former glory. By following the steps outlined in this article, you can diagnose and repair liquid-damaged devices, ensuring that your technology stays in top condition for years to come.

If you’re ever in doubt or need further assistance, don’t hesitate to reach out to the IT Fix team at https://itfix.org.uk/computer-repair/. We’re always here to lend a helping hand and ensure your devices are back up and running in no time.