Introduction to Computer Vision and Hardware Fault Detection

As an expert in the field of computer vision, I have witnessed the remarkable advancements in this technology and its growing importance in various industries, including hardware fault detection. Computer vision, the ability of machines to interpret and understand digital images and videos, has become a powerful tool in the realm of industrial automation and quality control.

In the context of hardware fault detection, computer vision can play a pivotal role in identifying defects, anomalies, and potential failures in physical devices and components. By leveraging the power of image processing, machine learning, and pattern recognition, computer vision systems can detect and analyze subtle changes, deviations, and irregularities that may be indicative of hardware faults.

One of the key advantages of using computer vision for hardware fault detection is the ability to automate the inspection process. Traditional manual inspections can be time-consuming, prone to human error, and often limited in their ability to detect complex or hard-to-see issues. Computer vision, on the other hand, can provide a systematic, consistent, and scalable approach to fault detection, allowing for the inspection of large volumes of hardware components with a high degree of accuracy and speed.

The Role of Computer Vision in Hardware Fault Detection

Computer vision plays a crucial role in the detection of hardware faults by enabling the following key functionalities:

1. Defect Detection

The primary function of computer vision in hardware fault detection is the identification of physical defects, such as cracks, scratches, discoloration, or deformities in the hardware components. By analyzing high-resolution images or video footage of the hardware, computer vision algorithms can detect and classify these defects with a high degree of precision, helping to ensure the quality and reliability of the final product.

2. Surface Inspection

In addition to detecting visible defects, computer vision can also be used to perform a comprehensive inspection of the hardware surface. This includes the identification of subtle imperfections, surface roughness, or irregularities that may not be easily discernible to the human eye. By capturing and analyzing detailed surface data, computer vision systems can provide valuable insights into the overall condition of the hardware, enabling early detection of potential issues.

3. Dimensional Measurement

Accurate dimensional measurements are crucial in hardware manufacturing, as deviations from the specified dimensions can lead to functional problems or compatibility issues. Computer vision can be used to perform precise measurements of various hardware components, such as length, width, thickness, or diameter, ensuring that the manufactured parts meet the required specifications.

4. Anomaly Detection

Computer vision algorithms can also be trained to detect anomalies or outliers in the hardware data, which may indicate the presence of a fault or an impending failure. By analyzing patterns and deviations from the expected behavior or appearance of the hardware, computer vision systems can identify potential issues that may not be immediately visible, allowing for proactive maintenance and preventive measures.

5. Predictive Maintenance

Leveraging the data gathered through computer vision-based inspection and analysis, machine learning models can be developed to predict the likelihood of hardware failures or the need for maintenance. This predictive maintenance approach can help organizations optimize their maintenance schedules, reduce downtime, and ensure the long-term reliability of their hardware assets.

Implementing Computer Vision for Hardware Fault Detection

Implementing computer vision for hardware fault detection typically involves the following key steps:

1. Image Acquisition

The first step is to capture high-quality images or video footage of the hardware components that need to be inspected. This may involve the use of specialized cameras, lighting, and positioning systems to ensure consistent and accurate image capture.

2. Image Preprocessing

Once the images or videos are acquired, they may need to be preprocessed to enhance their quality, remove noise, or perform other necessary transformations. This step can include techniques such as image normalization, color correction, or edge enhancement, depending on the specific requirements of the application.

3. Feature Extraction

The next step is to extract relevant features from the preprocessed images or videos that can be used to identify and classify hardware faults. This may involve the use of techniques such as edge detection, texture analysis, or shape recognition, depending on the type of defects or anomalies that need to be detected.

4. Machine Learning Model Training

With the extracted features, machine learning models can be trained to recognize patterns and detect faults in the hardware. This may involve the use of supervised learning algorithms, such as convolutional neural networks (CNNs) or support vector machines (SVMs), which are trained on a labeled dataset of images or video frames with known fault conditions.

5. Model Deployment and Monitoring

Once the machine learning model is trained and validated, it can be deployed in a real-world production environment to perform automated hardware fault detection. Continuous monitoring and feedback mechanisms can be implemented to further refine and improve the model’s performance over time, ensuring the ongoing effectiveness of the computer vision-based fault detection system.

Case Studies and Real-World Applications

To better illustrate the practical applications of computer vision for hardware fault detection, let’s explore a few real-world case studies:

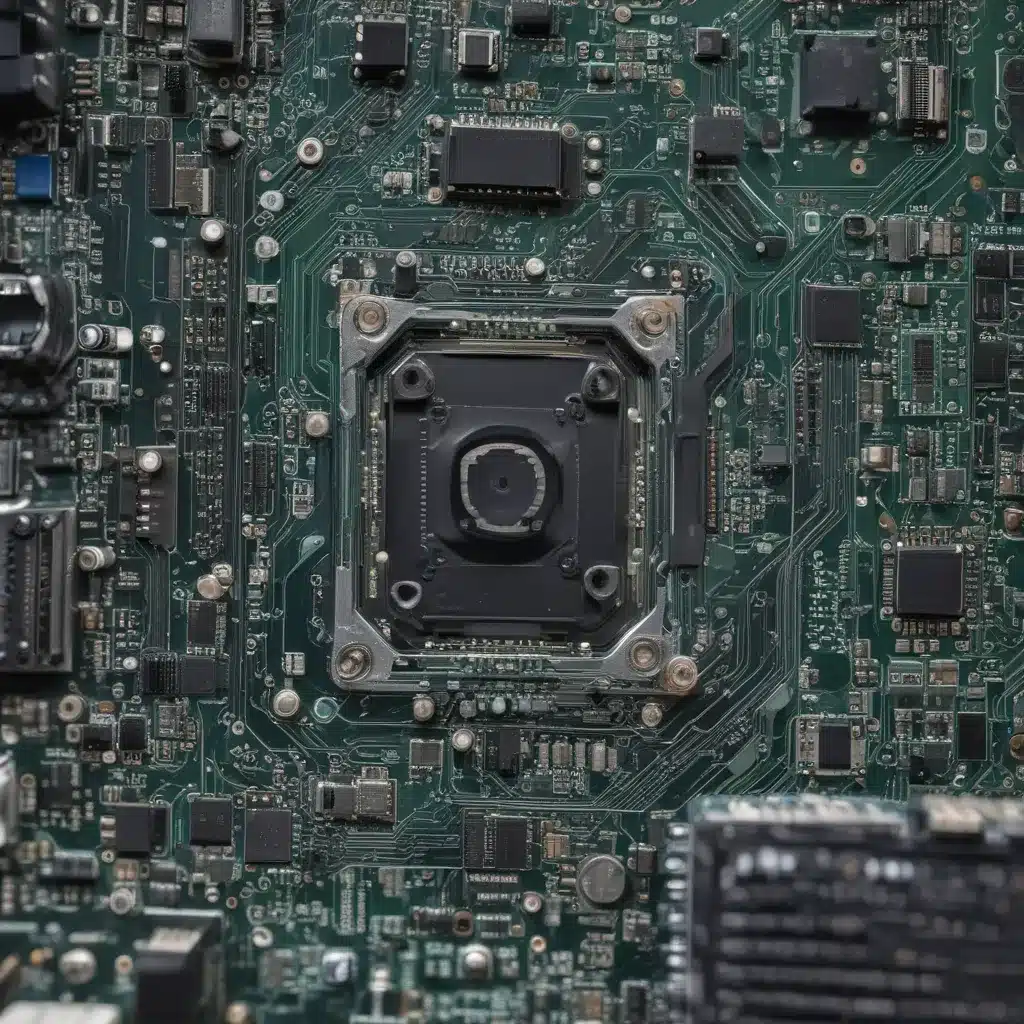

Case Study 1: Automated PCB Inspection

In the electronics manufacturing industry, printed circuit boards (PCBs) are critical components that require meticulous inspection to ensure quality and reliability. A leading electronics company implemented a computer vision-based inspection system to automate the process of identifying defects on PCBs.

The system used high-resolution cameras to capture detailed images of the PCBs, which were then processed by a deep learning model trained to detect a range of defects, including missing components, solder bridges, and trace damage. By automating the inspection process, the company was able to dramatically improve the efficiency and accuracy of their quality control, reducing the time and costs associated with manual inspections.

Case Study 2: Predictive Maintenance in Wind Turbines

In the renewable energy sector, wind turbines are critical infrastructure that require ongoing maintenance and monitoring to ensure reliable power generation. A wind turbine manufacturer partnered with a computer vision research team to develop a predictive maintenance system for their turbine components.

The system used computer vision algorithms to analyze high-resolution images and video footage of the turbine blades, gearboxes, and other critical components. By detecting subtle changes in the appearance, surface texture, or vibration patterns of these components, the system was able to predict the likelihood of future failures or the need for maintenance.

This proactive approach to maintenance allowed the wind turbine manufacturer to optimize their maintenance schedules, reduce unexpected downtime, and extend the overall lifespan of their turbine fleet.

Case Study 3: Automated Inspection of Automotive Parts

In the automotive industry, the quality and consistency of manufactured parts are essential to ensuring vehicle safety and performance. A leading automotive manufacturer implemented a computer vision-based inspection system to automate the process of detecting defects in their engine components, such as cylinder heads, pistons, and crankshafts.

The system utilized a combination of high-speed cameras, specialized lighting, and advanced computer vision algorithms to perform a comprehensive inspection of the parts at various stages of the manufacturing process. By automating this inspection, the company was able to achieve a significant reduction in defects, improve production efficiency, and ensure the consistent quality of their automotive components.

Challenges and Considerations in Implementing Computer Vision for Hardware Fault Detection

While the benefits of using computer vision for hardware fault detection are numerous, there are also several challenges and considerations that organizations should be aware of when implementing such systems:

1. Data Collection and Labeling

Effective machine learning models for hardware fault detection require large, high-quality datasets of labeled images or video frames. Collecting and accurately labeling this data can be a time-consuming and resource-intensive process, especially for complex or diverse hardware components.

2. Model Accuracy and Reliability

Ensuring the accuracy and reliability of computer vision-based fault detection models is critical, as false positives or negatives can have significant consequences in terms of production efficiency, quality control, and customer satisfaction. Rigorous testing, validation, and ongoing performance monitoring are essential to maintaining the effectiveness of these models.

3. Hardware and Infrastructure Requirements

Implementing computer vision for hardware fault detection may require specialized hardware, such as high-resolution cameras, advanced image processing units (IPUs), or dedicated computing infrastructure. Ensuring that the necessary hardware and infrastructure are in place can be a significant investment for organizations.

4. Integration with Existing Systems

Integrating computer vision-based fault detection systems with existing manufacturing, maintenance, or enterprise resource planning (ERP) systems can be a complex and challenging task. Ensuring seamless data exchange, process integration, and system interoperability is crucial for the effective implementation of these technologies.

5. Ethical and Regulatory Considerations

The use of computer vision and machine learning in industrial settings may raise ethical and regulatory concerns, such as data privacy, worker surveillance, or compliance with industry standards. Organizations must carefully consider these issues and ensure that their computer vision-based fault detection systems are designed and implemented in a responsible and ethical manner.

Conclusion

Computer vision has emerged as a powerful tool for enhancing hardware fault detection, offering a range of benefits in terms of automation, accuracy, and predictive maintenance. By leveraging the capabilities of image processing, machine learning, and pattern recognition, organizations can significantly improve the quality, reliability, and efficiency of their hardware manufacturing and maintenance processes.

As the field of computer vision continues to evolve and mature, the opportunities for its application in hardware fault detection will only continue to grow. By embracing these technologies and addressing the associated challenges, organizations can stay ahead of the curve, maintain a competitive edge, and ensure the long-term success and sustainability of their hardware-based products and services.