Matrix Manufacturing Systems: The Future of Flexible Production

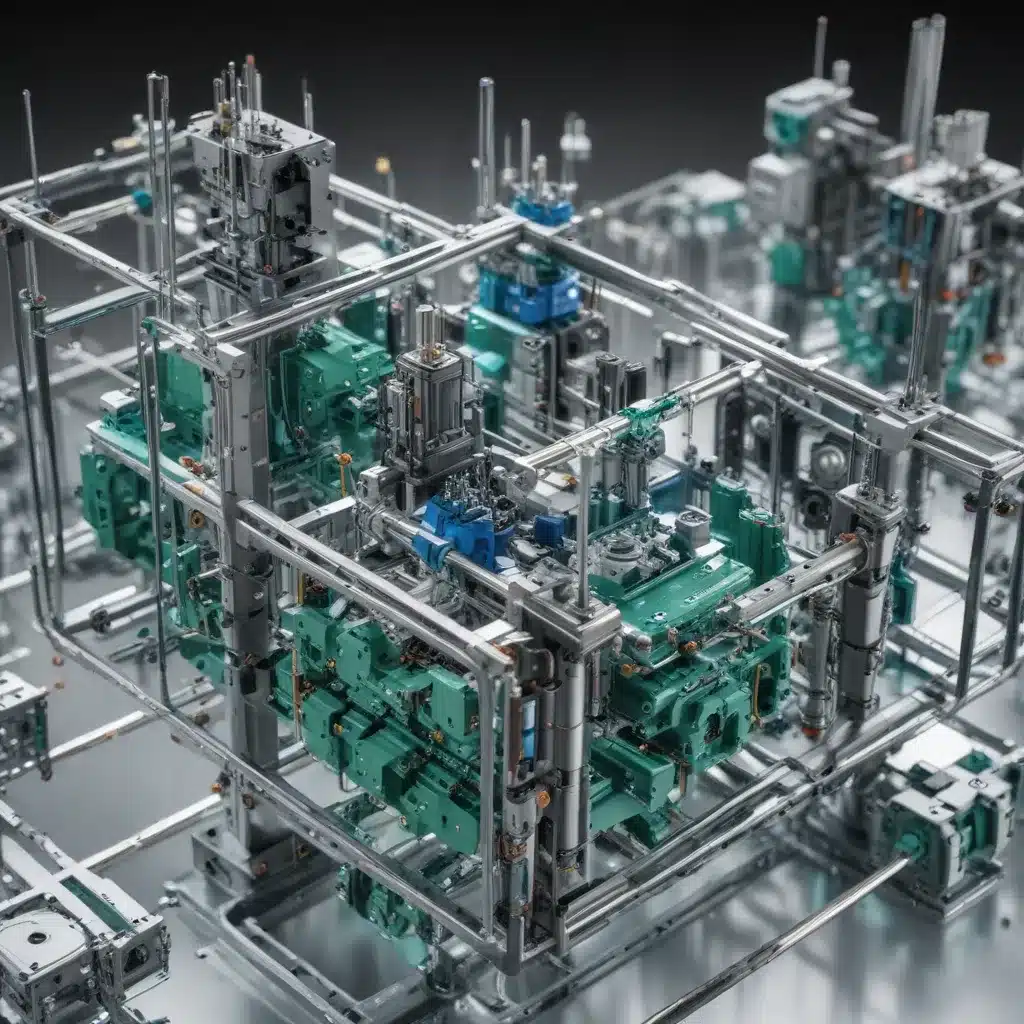

In the ever-evolving landscape of manufacturing, traditional flow-shop lines are no longer the optimal production paradigm. The rise of matrix manufacturing systems (MMS) offers a viable solution to the challenges faced by modern job-shops, enabling them to respond quickly to changes in demand and allocate resources more efficiently.

MMS: Redefining Flexibility and Adaptability

MMS are characterized by their high flexibility and strong adaptability, allowing them to reconfigure rapidly to suit varying production needs. Unlike traditional flow-shops, MMS are organized into matrix units (MUs) that can be quickly adjusted to accommodate different tasks and processes. This modular approach empowers manufacturers to allocate resources more effectively and improve overall equipment utilization.

Researchers at leading institutions, such as Braunschweig University of Technology and Karlsruhe Institute of Technology, have been at the forefront of MMS development. Their studies have demonstrated the significant advantages of MMS over dedicated flow-shops and reconfigurable manufacturing systems (RMS), including higher throughput rates, reduced work-in-progress, and more efficient waste management.

Optimizing MMS Performance with Overall Equipment Effectiveness (OEE)

While the inherent flexibility of MMS offers numerous benefits, optimizing their performance remains a critical challenge. This is where the concept of overall equipment effectiveness (OEE) comes into play. OEE is a widely-adopted metric that tracks improvements or declines in equipment efficiency, helping manufacturers identify and eliminate production process losses.

Traditionally, OEE has been used as a post-event indicator, providing limited guidance for real-time process control. However, by integrating machine learning algorithms, such as the synthetic minority oversampling technique and multilayer perceptron (SMOTE-MLP), it is possible to achieve online OEE calculation. This innovative approach enables MUs to make informed, data-driven decisions based on real-time efficiency indicators.

Collaborative Optimization: Unlocking the Full Potential of MMS

Leveraging the power of online OEE, a collaborative optimization model for MMS can be developed. This model empowers individual MUs to actively request tasks based on their efficiency levels, creating a dynamic, self-optimizing manufacturing ecosystem.

The key aspects of this collaborative optimization approach include:

Multi-Agent Collaboration: Intelligent agents, such as robots and automated equipment, work together to achieve global optimization, with interdependent task allocation for maximum efficiency.

Multistage/Line Collaboration: Effective control and coordination across production stages and lines ensure seamless workflow and minimize delays.

Production and Maintenance Collaboration: The joint optimization of scheduling and maintenance activities helps minimize downtime and costs.

Distributed Job-Shop Collaboration: Coordination between job-shops enhances resource utilization and task efficiency, addressing the challenges of flexible manufacturing environments.

Implementing Collaborative Optimization in a Matrix Manufacturing System

To demonstrate the practical application of collaborative optimization in MMS, let’s consider the example of a notebook assembly line at the Inventec Corporation.

The SMT (surface mount technology) production line at Inventec represents a typical flow-shop with inherent matrix and unit characteristics. The line can be divided into various MUs, such as the loading and printing unit, the chip mounting and reflow soldering unit, and the automated optical inspection (AOI) unit.

By leveraging the online OEE calculation model, the efficiency of each MU can be monitored in real-time. The MUs are then categorized into three levels based on their OEE: red (idle), yellow (good efficiency), and green (excellent efficiency).

The collaborative optimization model then comes into play, allocating additional tasks to the red and yellow MUs to improve their overall performance. This is achieved by integrating collaborative robot arms that can actively request tasks based on the MU’s OEE, prioritizing the low-efficiency units.

Through this dynamic, data-driven approach, the Inventec notebook assembly line was able to achieve significant improvements in OEE, with increases of 8.6%, 15.7%, and 18.6% for three of the SMT lines.

Unlocking the Future of Intelligent Manufacturing

The collaborative optimization of MMS, powered by online OEE calculations, represents a significant step forward in the quest for intelligent, adaptive manufacturing systems. By empowering individual MUs to make informed, data-driven decisions, manufacturers can unlock new levels of efficiency, flexibility, and responsiveness.

As the industry continues to evolve, the integration of advanced technologies, such as artificial intelligence and the Industrial Internet of Things, will further enhance the capabilities of MMS. The future of manufacturing lies in collaborative, self-optimizing systems that can seamlessly adapt to changing market demands and operational conditions.

The insights and strategies presented in this article offer a roadmap for IT professionals and manufacturing experts to navigate the exciting landscape of matrix manufacturing systems and collaborative optimization. By embracing these innovative approaches, you can unlock new opportunities for your organization and stay ahead of the curve in the ever-evolving world of industrial technology.

Visit https://itfix.org.uk/ to explore more cutting-edge IT solutions and industry insights.

Optimizing MMS Performance: A Step-by-Step Approach

Leveraging Online OEE Calculation

The key to effective collaborative optimization of MMS lies in the ability to monitor and analyze the efficiency of individual MUs in real-time. This is where the online OEE calculation model, powered by machine learning algorithms, plays a crucial role.

The SMOTE-MLP approach, which combines the synthetic minority oversampling technique and multilayer perceptron, enables the classification of various downtime types (normal production, planned, unplanned, and changeover) with high accuracy and efficiency. By continuously monitoring these factors, the system can calculate the OEE of each MU and classify them into the three categories: red (idle), yellow (good efficiency), and green (excellent efficiency).

Collaborative Optimization: Job Allocation and Task Insertion

With the real-time OEE data in hand, the collaborative optimization model can be implemented to enhance the performance of the MMS. The key components of this model include:

-

Multi-Agent Collaboration: Intelligent agents, such as collaborative robot arms, work together to allocate tasks and optimize the overall system performance.

-

Prioritized Job Allocation: The low-efficiency (red and yellow) MUs are prioritized for additional job insertions, allowing them to actively request tasks and improve their OEE.

-

Dynamic Task Insertion: The collaborative robot arms integrate the new tasks into the production workflow, synchronizing the various MUs to ensure seamless operation.

-

Continuous Optimization: The system continuously monitors the OEE of each MU and adjusts the task allocation accordingly, creating a self-optimizing manufacturing environment.

By implementing this collaborative optimization approach, the Inventec notebook assembly line was able to achieve significant improvements in OEE, demonstrating the power of this innovative strategy.

Conclusion: Embracing the Future of Intelligent Manufacturing

The collaborative optimization of matrix manufacturing systems, driven by online OEE calculations, represents a transformative shift in the way we approach industrial production. By empowering individual MUs to make informed, data-driven decisions, manufacturers can unlock new levels of flexibility, efficiency, and responsiveness.

As the industry continues to evolve, the integration of advanced technologies, such as artificial intelligence and the Industrial Internet of Things, will further enhance the capabilities of MMS. The future of manufacturing lies in collaborative, self-optimizing systems that can seamlessly adapt to changing market demands and operational conditions.

By embracing the insights and strategies presented in this article, IT professionals and manufacturing experts can play a crucial role in shaping the future of intelligent manufacturing. Explore the possibilities at https://itfix.org.uk/ and stay at the forefront of the industry’s transformation.