How IoT is Improving the Efficiency of the Manufacturing Industry

The manufacturing industry has undergone a paradigm shift over the years, thanks to technology. One such technology that has revolutionized the industry is the Internet of Things (IoT). IoT has made it possible to connect various devices and equipment to the internet, allowing for real-time data exchange and analysis. This has enabled manufacturers to streamline their operations, reduce costs, and boost efficiency. In this article, we will look at how IoT is transforming the manufacturing industry and what it means for the future.

What is IoT?

IoT refers to the interconnection of physical devices, vehicles, buildings, and other objects embedded with sensors, software, and network connectivity, enabling them to collect and exchange data. The concept of IoT is based on the idea of creating a network of smart devices that can communicate with each other, collect data, and make decisions based on that data. IoT has revolutionized the way we interact with technology, enabling us to automate tasks, monitor and control our environment, and make better decisions.

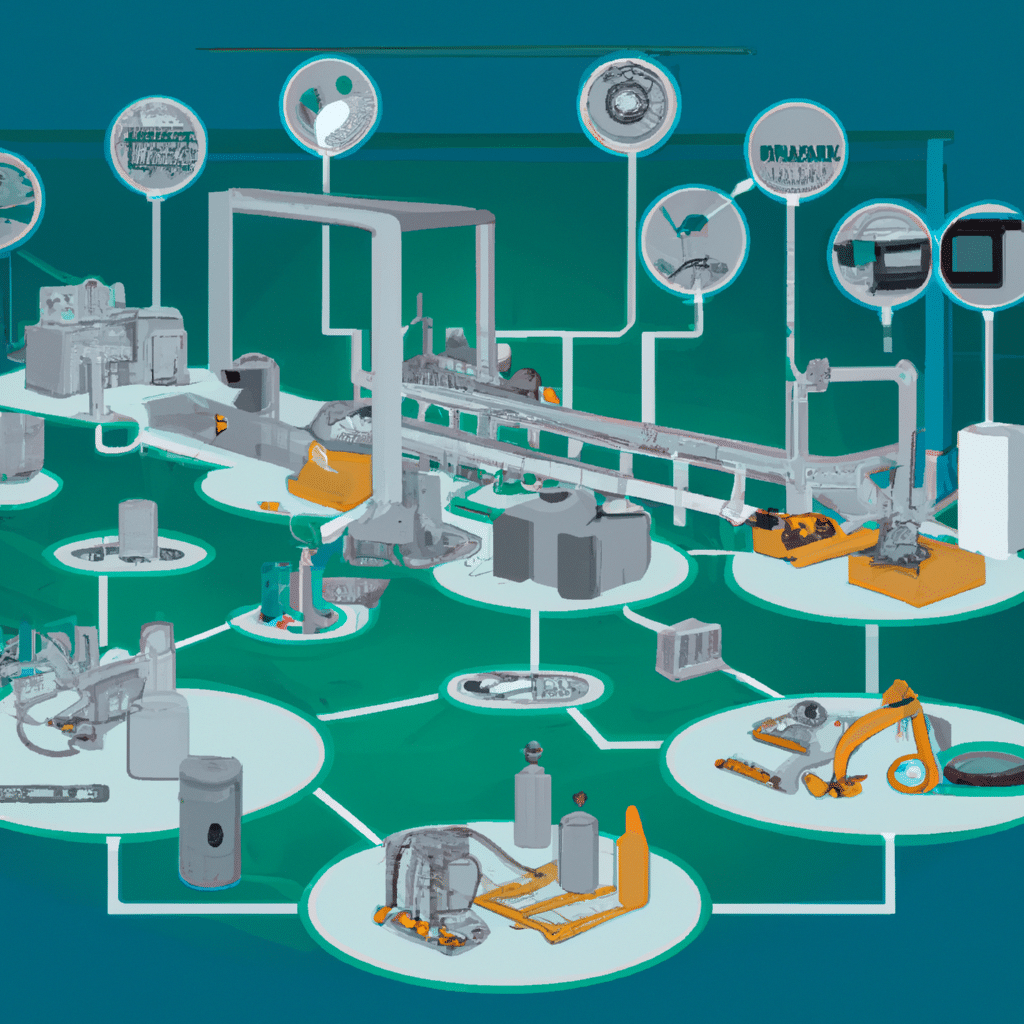

IoT in Manufacturing

The manufacturing industry is one of the sectors that has benefited greatly from IoT. With the help of IoT, manufacturers can now collect data from various sources such as machines, equipment, and products in real-time. This data can then be used to optimize production processes, reduce downtime, and improve product quality. IoT has also enabled manufacturers to monitor their operations remotely, allowing them to respond quickly to any issues that arise.

Predictive Maintenance

One of the most significant benefits of IoT in manufacturing is predictive maintenance. Predictive maintenance involves using real-time data to predict when equipment is likely to fail, allowing manufacturers to schedule maintenance before a breakdown occurs. This helps to reduce downtime, increase equipment lifespan, and improve overall efficiency. Predictive maintenance is becoming increasingly popular among manufacturers, with many companies investing heavily in IoT-based predictive maintenance systems.

Supply Chain Optimization

IoT has also enabled manufacturers to optimize their supply chain operations. By collecting data from various sources such as suppliers, warehouses, and transportation systems, manufacturers can gain insights into their supply chain and identify areas for improvement. This can help to reduce costs, improve delivery times, and enhance overall efficiency. IoT-based supply chain optimization systems are becoming increasingly popular, with many companies already implementing them.

Quality Control

IoT has also revolutionized quality control in the manufacturing industry. By collecting data from various sources such as sensors and cameras, manufacturers can monitor their production processes in real-time and identify any defects or quality issues. This allows them to take corrective action immediately, reducing waste, and improving product quality. IoT-based quality control systems are becoming increasingly popular, with many companies already using them.

Conclusion

IoT has transformed the manufacturing industry, enabling manufacturers to streamline their operations, reduce costs, and boost efficiency. With IoT-based predictive maintenance, supply chain optimization, and quality control systems becoming increasingly popular, we can expect to see even more significant changes in the future. As IoT technology continues to evolve, we can expect to see more manufacturers adopting it to gain a competitive advantage. The future of manufacturing looks bright with IoT.